Click on one of the "SEE PACKAGE" buttons above to see the details for that option. Please contact us for additional options that suite your application.

We offer a free tier, where one reading per day is provided. Data frequencies as granular as 1x/minute can be provided with an additional monthly fee.

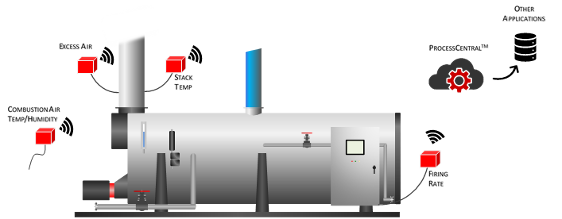

The goal is to make installation as simple as possible. The stack temperature probe has a 1/4"MNPT threaded connection to be installed in the stack. An existing temperature value can also be utilized with a 4-20mA signal.

The combustion air conditions are monitored with our AmbiAirTM RemoteLobe, and simply needs to be in the boiler room near the boiler air intake.

The firing rate is to be obtained from an existing control system via a 4-20mA reading to a RemoteLobeTM.

The excess air/oxygen is obtained from an existing sensor or control system via a 4-20mA reading to a RemoteLobeTM.

Yes, please contact us for a custom package. Essentially you wouldn't need 2 AmbiAirTM devices assuming the boilers were in the same room.

The ProcessEyeTM ecosystem uses standard WiFi, which enables the sensors and RemoteLobesTM to be dispersed throughout a facility. They can be granted access to a Guest-WiFi network, or a separate cellular modem with a hotspot can be used to gain access to the internet.

Absolutely. We have allowed users a robust reporting package in ProcessCentralTM that allows them to generate custom reports on a frequency that is desirable to them (i.e. daily, weekly, or monthly).

Security is one of our key priorities and we use the most advanced encryption technology available to ensure secure communications.

Our ecosystem uses a blend of computing logic that occurs in our RemoteLobesTM as well as ProcessCentralTM, so at this point we don't make the information available to be incorporated into existing infrastructure. We also believe that there isn't much value in bringing this data into existing infrastructure due to the cost, complexities and lack of automated reporting. Without the reporting capabilities the same "forgotten" condition will develop and users and organizations won't be any better off.