The risks associated with Legionella and bacteria that cause other water-borne illnesses are becoming better understood. Facilities have typically developed risk-management plans focusing on identifying potential risk points, how those risks will be prevented, how testing will be conducted and what steps will be taken in the event of a positive test result. The current focus has been primarily reactive in nature and not much emphasis has been placed on a comprehensive, proactive risk-monitoring program.

SOL-RISKEYE

RISKEYETM

THE PROBLEM

THE SOLUTION

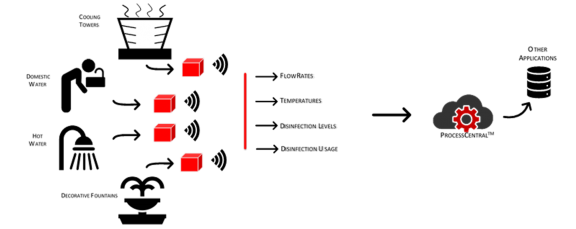

Our RiskEyeTM Monitoring Program enables a facility to proactively monitor critical risk parameters throughout their facility…from the utility room to the operating room. The parameters measured are all-encompassing and range from temperature to oxidant levels to validating the use of disinfectants. ProcessEye’s wide variety of sensors interface with RemoteLobesTM, which are mini-computers with WiFi capability. Users connect easily via any WiFi device to configure the sensors and access the internet. There is no need to report back to a central monitoring location, so the sensors can be located anywhere…in the basement or on the rooftop. No special software, cables, wiring, drivers, etc. are required.

From the RemoteLobesTM, data begins to flow to our highly-secured web platform, called ProcessCentralTM, where the rest of the value is derived. All risk points can be brought together in one dashboard with user-independent alarm thresholds. For example, if a remote hot water loop drops below 122oF, a non-oxidizing inventory level has not changed, or the disinfection levels in the domestic water or cooling tower fall below a defined level, the maintenance staff can be notified so immediate corrective actions can be taken to reduce the health risks associated with Legionella and other water-borne illnesses.

The RiskEyeTM program helps to:

- Reduce risk by taking a broad, proactive approach with automatic documentation

- Reduce installation costs by using WiFi technology rather than pulling cables and doing custom programming

- Reduce operational costs by eliminating the need for operations personnel to do rounds and record values

- Rapidly correct conditions that result in higher risks

We offer 2 standard packages for both domestic water systems and cooling towers that have been developed depending on the degree of information desired (other options available). The information for these packages is contained below.

STANDARD DRINKING WATER PACKAGES

STANDARD TOWER PACKAGES

RESOURCES

FAQs

Click on one of the "SEE PACKAGE" buttons above to see the details for that option. Please contact us for additional options that suite your application.

We offer a free tier, where one reading per day is provided. Data frequencies as granular as 1x/minute can be provided with an additional monthly fee.

Unlike normal data monitoring, our ProcessEye ecosystem doesn't rely on wires being pulled back to one main location. Instead we use WiFi, which allows for the monitoring points to be distributed throughout the facility. The goal is to make installation as simple as possible. For temperature sensing you can either use temperature probes that have a 1/4"MNPT threaded connection to be installed in the water stream. An alternative is to use a T2 Series surface mounted temperature sensor that can be affixed to the outside of a pipe, and underneath insulation. It's not as fast to respond and it's absolute reading won't be as accurate as an inserted sensor; however, for trending purposes it can be sufficient. Existing temperature values can also be utilized with a 4-20mA signal.

Oxidant, or disinfection levels, can be monitored by using an online analyzer and sending a 4-20mA signal to a RemoteLobeTM.

Inventory levels of the chemicals are monitored using our industry leading LevelEyeTM Program. This program requires no special fittings, only dropping a sensor into a drum or tank.

The cooling tower health is monitored using our Basic TowerEyeTM Program. This involves a user dropping sensors into the cooling tower distribution deck and basin as well as hanging a sensor outside out of the elements.

The first temperature sensor is to monitor the temperatures at the source (i.e. in the utility room before being distributed to the facility). The second sensor is located in a remote part of the facility. The difference between these two values gives users and indication of the amount of temperature gain (in the case of cold water) or the temperature loss (in the case of hot water). To reduce the risk of Legionella you want to keep water temperatures outside of the optimal range for Legionella growth.

No they are not. You would use an appropriate analyzer and then send a standard 4-20mA signal to our RemoteLobeTM.

The ProcessEyeTM ecosystem uses standard WiFi, which enables the sensors and RemoteLobesTM to be dispersed throughout a facility. They can be granted access to a Guest-WiFi network, or a separate cellular modem with a hotspot can be used to gain access to the internet.

Absolutely. We have allowed users a robust reporting package in ProcessCentralTM that allows them to generate custom reports on a frequency that is desirable to them (i.e. daily, weekly, or monthly).

Security is one of our key priorities and we use the most advanced encryption technology available to ensure secure communications.

Our ecosystem uses a blend of computing logic that occurs in our RemoteLobesTM as well as ProcessCentralTM, so at this point we don't make the information available to be incorporated into existing infrastructure. We also believe that there isn't much value in bringing this data into existing infrastructure due to the cost, complexities and lack of automated reporting. Without the reporting capabilities the same "forgotten" condition will develop and users and organizations won't be any better off.

RISKEYETM

THE PROBLEM

The risks associated with Legionella, and those that cause other water-borne illnesses, are becoming better understood. Facilities have typically developed risk management plans focusing on identifying potential risk points, how those risks will be prevented, how testing will be conducted and what steps will be taken in the event of a positive test result. The current focus has been primarily reactive in nature and not much emphasis has been placed on a comprehensive, proactive risk monitoring program.

THE SOLUTION

Our RiskEyeTM Monitoring Program enables a facility to proactively monitor critical risk parameters throughout their facility…from the utility room to the OR. The parameters measured are all-encompassing and range from temperature to oxidant levels to validating the use of disinfectants. ProcessEye’s wide variety of sensors interface with RemoteLobesTM, which are mini-computers with WiFi capability. Users connect easily via any WiFi device to configure the sensors and access the internet. There is no need to report back to a central monitoring location, so the sensors can be located anywhere…in the basement or on the rooftop. No special software, cables, wiring, drivers, etc. are required.

From the RemoteLobesTM, data begins to flow to our highly-secured web platform, called ProcessCentralTM, where the rest of the value is derived. All risk points can be brought together in one dashboard with user-independent alarm thresholds. For example, if a remote hot water loop drops below 122oF, or a non-oxidizing inventory level hasn’t changed, or the disinfection levels in the domestic water or cooling tower fall below a defined level, the maintenance staff can be notified so immediate corrective actions can be taken to reduce the health risks associated with Legionella and other water-borne illnesses.

The RiskEyeTM program helps to:

- Reduce Risk by taking a broad, proactive approach with automatic documentation

- Reduce Installation Costs by using WiFi technology rather than pulling cables and doing custom programming

- Reduce Operational Costs by not needing operations personnel doing rounds and recording values

- Rapid Correction to conditions resulting in higher risk

There are 2 standard packages for both domestic water systems and cooling towers that have been developed depending on the degree of information desired (other options available). The information for these packages is contained below.

STANDARD DRINKING PACKAGES

STANDARD TOWER PACKAGES

RESOURCES

FAQs

Click on one of the "SEE PACKAGE" buttons above to see the details for that option. Please contact us for additional options that suite your application.

We offer a free tier, where one reading per day is provided. Data frequencies as granular as 1x/minute can be provided with an additional monthly fee.

Unlike normal data monitoring, our ProcessEye ecosystem doesn't rely on wires being pulled back to one main location. Instead we use WiFi, which allows for the monitoring points to be distributed throughout the facility. The goal is to make installation as simple as possible. For temperature sensing you can either use temperature probes that have a 1/4"MNPT threaded connection to be installed in the water stream. An alternative is to use a T2 Series surface mounted temperature sensor that can be affixed to the outside of a pipe, and underneath insulation. It's not as fast to respond and it's absolute reading won't be as accurate as an inserted sensor; however, for trending purposes it can be sufficient. Existing temperature values can also be utilized with a 4-20mA signal.

Oxidant, or disinfection levels, can be monitored by using an online analyzer and sending a 4-20mA signal to a RemoteLobeTM.

Inventory levels of the chemicals are monitored using our industry leading LevelEyeTM Program. This program requires no special fittings, only dropping a sensor into a drum or tank.

The cooling tower health is monitored using our Basic TowerEyeTM Program. This involves a user dropping sensors into the cooling tower distribution deck and basin as well as hanging a sensor outside out of the elements.

The first temperature sensor is to monitor the temperatures at the source (i.e. in the utility room before being distributed to the facility). The second sensor is located in a remote part of the facility. The difference between these two values gives users and indication of the amount of temperature gain (in the case of cold water) or the temperature loss (in the case of hot water). To reduce the risk of Legionella you want to keep water temperatures outside of the optimal range for Legionella growth.

No they are not. You would use an appropriate analyzer and then send a standard 4-20mA signal to our RemoteLobeTM.

The ProcessEyeTM ecosystem uses standard WiFi, which enables the sensors and RemoteLobesTM to be dispersed throughout a facility. They can be granted access to a Guest-WiFi network, or a separate cellular modem with a hotspot can be used to gain access to the internet.

Absolutely. We have allowed users a robust reporting package in ProcessCentralTM that allows them to generate custom reports on a frequency that is desirable to them (i.e. daily, weekly, or monthly).

Security is one of our key priorities and we use the most advanced encryption technology available to ensure secure communications.

Our ecosystem uses a blend of computing logic that occurs in our RemoteLobesTM as well as ProcessCentralTM, so at this point we don't make the information available to be incorporated into existing infrastructure. We also believe that there isn't much value in bringing this data into existing infrastructure due to the cost, complexities and lack of automated reporting. Without the reporting capabilities the same "forgotten" condition will develop and users and organizations won't be any better off.