Heat exchangers are arguably some of the most important units within an industrial facility. They are responsible for the heating and cooling of various fluids for a wide variety of purposes. While most heat exchangers serve a critical purpose, very few have the necessary instrumentation and managerial oversight to enable personnel to know how they are performing. The result is decreased efficiencies, reduced production, increased maintenance, shortened equipment life and, in some cases, reduced safety.

SOL-TRANSFEREYE

TRANSFEREYETM

THE PROBLEM

THE SOLUTION

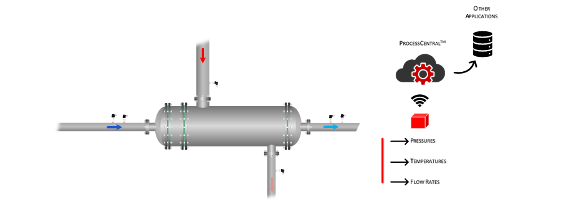

Our TransferEyeTM Heat Exchanger Efficiency Monitoring Program can utilize a combination of existing and new instrumentation to easily and effectively monitor heat exchanger performance. The parameters that need to be monitored are a function of the type of heat exchanger, as well as the operating dynamics of the system. In some cases, the conditions might be very steady-state, and the outlet temperature of the fluids might be the only thing that needs to be monitored to get an indication of how the heat transfer surfaces are. In other cases, there might be a need for more extensive monitoring, such as the temperature in/out of the cooling fluid, temperature in/out of the process fluid, pressure in/out of the cooling fluid, pressure in/out of all fluids, and/or flow rates of one or both fluids.

To accomplish extensive monitoring of heat exchanger performance, we provide sensors that are connected to RemoteLobesTM, which are mini-computers with WiFi capability, with a simple screw-connect electrical fitting. Users can easily connect to our RemoteLobesTM via any WiFi device to configure sensors on the heat exchanger. No special software, cables, wiring, drivers, etc. are required. There is not a simpler installation or configuration process for heat exchanger monitoring on the market.

These readings are transmitted wirelessly to ProcessCentralTM, where custom analytics are utilized. Users can easily develop calculated variables using the various sensor inputs as sources. Variables for ΔP, ΔT, LMTD and overall heat transfer efficiencies can be written effortlessly by any user. The data within ProcessCentralTM can be kept internal to the organization, or it can be shared with companies that can directly impact their heat exchanger performance, such as cleaning companies, process experts or water treatment specialists.

The TransferEyeTM program helps to:

- Protect asset integrity

- Prevent downtime by being predictive

- Improve safety by ensuring proper cooling of critical applications

- Simplify operations by not needing IT/OT personnel to get started

We offer 3 standard packages that have been developed depending on the degree of information desired (other options available). The information for these packages is contained below.

STANDARD PACKAGES

RESOURCES

FAQs

Click on one of the "SEE PACKAGE" buttons above to see the details for that option. Please contact us for additional options that suite your application.

We offer a free tier, where one reading per day is provided. Data frequencies as granular as 1x/minute can be provided with an additional monthly fee.

The goal is to make installation as simple as possible. For temperature sensing you can either use temperature probes that have a 1/4"MNPT threaded connection to be installed in the process stream. An alternative is to use a T2 Series surface mounted temperature sensor that can be affixed to the outside of a pipe, and underneath insulation. It's not as fast to respond and it's absolute reading won't be as accurate as an inserted sensor; however, for trending purposes it can be sufficient. Existing temperature values can also be utilized with a 4-20mA signal.

If differential pressure values are desired, either 2x P1 Series pressure transmitters or 1x D1 Series differential pressure transmitters can be used. Both models have 1/4"MNPT fittings.

If flow measurements are desired to determine the overall heat transfer efficiency, either an existing flow signal can be used (via a 4-20mA input to a RemoteLobeTM) or a U1 Series transit-time ultrasonic flow meter can be used that simply attaches to the outside of a pipe.

LMTD is an acronym of Log Mean Temperature Difference. It is an important value in heat exchangers that don't experience phase changes as it is the driving force for the heat exchange between the two fluids. As the LMTD value increases, the amount of heat transfer between the two fluids also increases. The formula can be given by:

ΔTLMTD = (ΔT2 - ΔT1) / ln(ΔT2 / ΔT1)

Yes. You would essentially order 2x Basic packages.

Users have free access to ProcessCentralTM and in there you can created calculated fields. Using the input values from the RemoteLobesTM as the source of the data, you can write a formula to determine the resulting variable you would like trended and reported on.

The ProcessEyeTM ecosystem uses standard WiFi, which enables the sensors and RemoteLobesTM to be dispersed throughout a facility. They can be granted access to a Guest-WiFi network, or a separate cellular modem with a hotspot can be used to gain access to the internet.

Absolutely. We have allowed users a robust reporting package in ProcessCentralTM that allows them to generate custom reports on a frequency that is desirable to them (i.e. daily, weekly, or monthly).

Security is one of our key priorities and we use the most advanced encryption technology available to ensure secure communications.

Our ecosystem uses a blend of computing logic that occurs in our RemoteLobesTM as well as ProcessCentralTM, so at this point we don't make the information available to be incorporated into existing infrastructure. We also believe that there isn't much value in bringing this data into existing infrastructure due to the cost, complexities and lack of automated reporting. Without the reporting capabilities the same "forgotten" condition will develop and users and organizations won't be any better off.

TRANSFEREYETM

THE PROBLEM

Heat exchangers are arguably some of the most units within an industrial facility. They are responsible for the heating and cooling of various fluids for a wide variety of purposes. While most heat exchangers serve a critical purpose, very few have the necessary instrumentation and managerial oversight to enable personnel to know how they are performing. The result is decreased efficiencies, reduced production, increased maintenance, shortened equipment life and, in some cases, reduced safety.

THE SOLUTION

Our TransferEyeTM Heat Exchanger Efficiency Monitoring Program can utilize a combination of existing and new instrumentation to easily and effectively monitor heat exchanger performance. The parameters that need to be monitored are a function of the type of heat exchanger as well as the operating dynamics of the system. In some cases, the conditions might be very steady-state, and the outlet temperature of the fluids might be the only thing that needs to be monitored to get an indication of how the heat transfer surfaces are. In other cases, there might be the need more extensive monitoring, such as the temperature in/out of the cooling fluid, temperature in/out of the process fluid, pressure in/out of the cooling fluid, pressure in/out of all fluids, and/or flow rates of one or both fluids.

To accomplish extensive monitoring of heat exchanger performance, we provide sensors that are connected to RemoteLobesTM, which are mini-computers with WiFi capability, with a simple screw connect electrical fitting. Users can easily connect to our RemoteLobesTM via any WiFi device to configure sensors on the heat exchanger. No special software, cables, wiring, drivers, etc. are required. There is not a simpler installation or configuration process for heat exchanger monitoring on the market.

These readings are transmitted wirelessly to ProcessCentralTM, where custom analytics are utilized. Users can easily develop calculated variables using the various sensor inputs as sources. Variables for ΔP, ΔT, LMTD and overall heat transfer efficiencies can be written effortlessly by any user. The data within ProcessCentralTM can be kept internal to the organization, or it can be shared with companies that can directly impact their cleaning companies, process or water treatment specialists.

The TransferEyeTM program helps to:

- Protect asset integrity

- Prevent Downtime by being predictive

- Improve Safety by ensuring proper cooling of critical applications

- Simplify by not needing IT/OT personnel to get started

There are 3 standard packages that have been developed depending on the degree of information desired (other options available). The information for these packages is contained below.

STANDARD PACKAGES

RESOURCES

FAQs

Click on one of the "SEE PACKAGE" buttons above to see the details for that option. Please contact us for additional options that suite your application.

We offer a free tier, where one reading per day is provided. Data frequencies as granular as 1x/minute can be provided with an additional monthly fee.

The goal is to make installation as simple as possible. For temperature sensing you can either use temperature probes that have a 1/4"MNPT threaded connection to be installed in the process stream. An alternative is to use a T2 Series surface mounted temperature sensor that can be affixed to the outside of a pipe, and underneath insulation. It's not as fast to respond and it's absolute reading won't be as accurate as an inserted sensor; however, for trending purposes it can be sufficient. Existing temperature values can also be utilized with a 4-20mA signal.

If differential pressure values are desired, either 2x P1 Series pressure transmitters or 1x D1 Series differential pressure transmitters can be used. Both models have 1/4"MNPT fittings.

If flow measurements are desired to determine the overall heat transfer efficiency, either an existing flow signal can be used (via a 4-20mA input to a RemoteLobeTM) or a U1 Series transit-time ultrasonic flow meter can be used that simply attaches to the outside of a pipe.

LMTD is an acronym of Log Mean Temperature Difference. It is an important value in heat exchangers that don't experience phase changes as it is the driving force for the heat exchange between the two fluids. As the LMTD value increases, the amount of heat transfer between the two fluids also increases. The formula can be given by:

ΔTLMTD = (ΔT2 - ΔT1) / ln(ΔT2 / ΔT1)

Yes. You would essentially order 2x Basic packages.

Users have free access to ProcessCentralTM and in there you can created calculated fields. Using the input values from the RemoteLobesTM as the source of the data, you can write a formula to determine the resulting variable you would like trended and reported on.

The ProcessEyeTM ecosystem uses standard WiFi, which enables the sensors and RemoteLobesTM to be dispersed throughout a facility. They can be granted access to a Guest-WiFi network, or a separate cellular modem with a hotspot can be used to gain access to the internet.

Absolutely. We have allowed users a robust reporting package in ProcessCentralTM that allows them to generate custom reports on a frequency that is desirable to them (i.e. daily, weekly, or monthly).

Security is one of our key priorities and we use the most advanced encryption technology available to ensure secure communications.

Our ecosystem uses a blend of computing logic that occurs in our RemoteLobesTM as well as ProcessCentralTM, so at this point we don't make the information available to be incorporated into existing infrastructure. We also believe that there isn't much value in bringing this data into existing infrastructure due to the cost, complexities and lack of automated reporting. Without the reporting capabilities the same "forgotten" condition will develop and users and organizations won't be any better off.