Liquid tanks have historically been left to manual monitoring and have therefore been susceptible to manufacturing and logistics inefficiencies, compromised systems and generally a lot of frustration. Up to this point, automatic tank level sensing has typically been done via ultrasonic level measurement. The challenges with ultrasonic technologies are:

- Ultrasonic level sensor accuracy can be impacted by ambient temperature, humidity and the composition of the vapor phase above the liquid level.

- Ultrasonic level sensors require certain ports. Often this might be a 2” NPT fitting, which a tank might not have, or which is already being utilized by something else, like a fill line connection

- Ultrasonic sensors require specific monitoring locations so that the sidewalls of the tank don’t impact the cone beam pattern of the sensors. So not only does the tank need the proper hole size, but it also must be in the correct location.

- Ultrasonic sensors need, often expensive, controllers to receive their signals, interpret the readings and send the data to the cloud.

While our LevelEyeTM Tank Level Monitoring Program can utilize any level-sensing device with a 4-20mA output, our standard program utilizes differential pressure transmitters. This eliminates the challenges encountered with ultrasonic level sensing and provides a more universal and accurate solution.

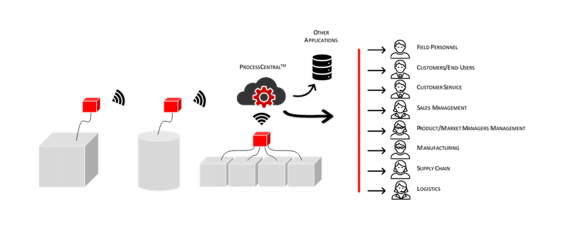

Our RemoteLobesTM, which are mini-computers with WiFi capability, allow a user to connect easily via WiFi. No special software, cables, wiring, drivers, etc. are required. Each device is easily configured in a secured web browser. There is not a simpler installation or configuration process for tank level monitoring on the market.

From the RemoteLobeTM, data begins to flow to our highly- secured web platform, called ProcessCentralTM, where the rest of the magic happens. Our back-end structure was built with scalability and flexibility in mind. The infrastructure enables our users to add values to over 30 different fields for each tank, thereby enabling easy reporting and analysis segmented by a wide variety of parameters to include things like personnel, application, product, warehouse source, geography, etc.

The LevelEyeTM program helps to:

- Eliminate stress by knowing your inventory levels are in control

- Protect assets by ensuring sufficient inventory is on sight at all times

- Save time by getting data into the hands of those that execute order replenishment

- Reduce Costs by being able to accurately forecast manufacturing & supply chain

There are 4 standard sensor configurations available to help meet most all chemical compatibility concerns. The information for these standard options is contained below.