There are many analogies to business and sports, as well as business and chess. In all cases the parties involved are looking to gain a competitive advantage. Maybe sports teams are scouting to understand their competitor’s playbooks, or a chess player is trying to get a pawn across the board to get a 2nd queen (yes, that is legal), or a service company is trying to figure out how to deliver more value at a reduced cost. In the world of business, the continuous race for better, faster, cheaper exists whether companies are manufacturing widgets or companies are suppliers of goods and services.

For many suppliers the race has taken its toll, it’s participants succumbing to the belief that price is the only differentiator. In many situations, that is the case. Competitive adaptation rates have been faster than innovation. Lacking true differentiation has caused customers to make more decisions based on price, discounting features and benefits due to the perception that another supplier can provide the same.

Many manufacturers have accepted the fact that they have done as much as they can. They perceive that there are no more gains in efficiency or productivity to be had and they have entered “status-quo” mode.

While suppliers and manufacturers face different challenges, in many cases their situations are very similar. There hasn’t been something that enables a step-wise change in how they operate or what they deliver to a customer.

Enter the Industrial Internet of Things (IIoT). For those unfamiliar or confused with “IIoT” you can find out more here. Unlike the glamour of self-driving cars, sending rockets into orbit or other innovations, the very basic fruit of IIoT is data. Data that has been previously unavailable, data that enables challenging status-quo, data that enables identifying areas for opportunity, data that enables true differentiation.

“…the very basic fruit of IIoT is data.”

If you’re still a skeptic of the value of data, look at Google or Facebook. They are two of the most profitable companies, whose product is primarily…data. Some might say Google and Facebook’s data is different than the data that can be provided by IIoT. That is true; however, data enabled those companies to generate industries from nothing. Very few could have ever predicted what Google or Facebook would become with just data.

But Google and Facebook didn’t rest on just having the data, they figured out a way to leverage its value. Some organizations might say “We have more data than we know what to do with already.” That’s probably true; however, it’s also a relative statement and one that might imply that the data they are currently collecting might be in a poor format, or missing other pieces of the puzzle, or it’s simply not in the hands of those it should be. Properly structured IIoT solutions, like ProcessEye, understand the value isn’t necessarily the data itself, rather being able to easily transform the data into actionable knowledge. It shouldn’t be simply about how to gather more data, rather how to convert that data into a competitive advantage.

“Properly structured IIoT solutions, like ProcessEye, understand the value isn’t necessarily the data itself, rather being able to easily transform the data into actionable knowledge.”

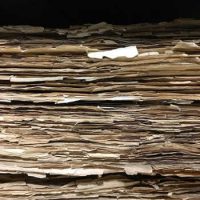

An example of poorly formatted data would be the countless manual log sheets that decorate facilities across the world. Some might suspect the proliferation of these logs sheets to be attributed to a conspiracy theory involving the pulp and paper industry, but the real reason is that “back in the day” there was no other reasonable solution to keep an eye on these processes. Also “back in the day” there was enough labor to take these readings as well as manage them, something that has typically been lost over time. Now organizations are flying blind and, in many cases, not knowing what they don’t know.

“It shouldn’t be simply about how to gather more data, rather how to convert that data into a competitive advantage.”

Beyond the poor format of data, there might be the case of missing data to be able to derive any value. A facility might want to know the heat transfer efficiency of a heat exchanger; however, they lack a flow or temperature reading that enables them to convert this data into actionable knowledge. Without those missing points, the other data is of relatively little value.

Finally, information is only as good as the people whose hands it’s in. Take for example industrial facilities that have central control systems that keep a process going. Most hours of the day have operators “manning the boards” to know if something goes awry and to respond accordingly. The challenge is that these operators aren’t trained, nor do they have the time, to analyze the data they are seeing. Many times, organizations have down-sized and no longer have anyone that can proactively prevent or improve anything. IIoT can enable extracting value out of these types of legacy systems as well as adding additional data points with ease. It can make it easy to convert data points into actionable knowledge without a lot of human intervention. It can also make it possible to share access to this data easily…across geographical and organizational boundaries so other employees, consultants or suppliers can provide knowledgeable insight.